Paper Making

AQUA+TECH is producing products used in the process and waste water treatment for pulp mills, in newsprint and liner board as well as retention aids for fine paper. One example case study will be show for tissue paper.

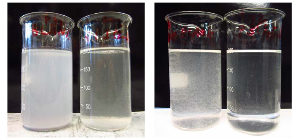

Polymac improves the production speed and yield in the manufacturing of toilet, facial and napkin grades of tissues. It is a unique chemistry which binds to the fiber, changing the conformation and, thereby, permitting faster drainage. As the fines are collected and put onto the sheet, there white water is cleaner (Figure 1).

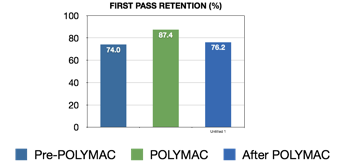

Cleaner water also equates to a higher first pass retention (typically 5-10%), less dusting and on drying limited machines, a higher throughput. If speed is not required, the drainage improvement will permit the production of tissue with lower steam, gas and electricity, on average by 1-3%. As fines are retained, though ash is not, on secondary furnishes or direct entry machines, whiter tissue can be produced (Figure 2)

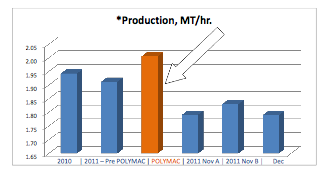

Figure 3 shows an ABA trial on a high speed tissue machine, capable of running at 2000+ m/min. Even for the highest technologies, the polymer is able to complement the mechanical technology and pass on savings. There is no reduction in tensiles or negative effects in adding Polymac and, as there is less breakage, process waste is reduced. In keeping the water clean, Polymac permits a more closed water loop.

A plot of average production, for a six month period, with and without Polymac is shown in Figure 4. The use of Polymac can reduce the consumption of cationic starch. As it is a natural coating, the level of “release” agent can also be lower on facial grades. Polymac was developed by Gerhard Viljoen and Julien Arnold. It is a food grade product (Halal) and has received the Nordic Swann ecolabel. Several grades are available.

Figure 1. White Water

(Left. No-Polymac, Right with Polymac)

Recycled Fiber

Virgin Fiber

Figure 2. Jumbo Roll after the Addition of Polymac.

Polymac Added

Figure 3. First Pass Retention before, during and after Polymac addition.

Figure 4. Production before (blue) and with (orange) Polymac on a 16.5 gsm facial machine.

Tissue Manufacturing with Polymac gives an improved drainage, higher first pass retention (2), reduced energy consumption 3) and higher production rate (4).

Higher Retention

Cleaner White Water

Lower Energy

Higher Production